- WEDNESDAY, MAY 8, 2024

Roger Williams opens innovative state-of-the-art engineering building

Engineering, computer science and construction management hub already buzzing with activity

It’s been a busy year for Jim Dorothy, Roger Williams University professor and director of operations for their School of Engineering. The university’s latest addition, the SECCM Labs …

This item is available in full to subscribers.

Please log in to continue |

Register to post eventsIf you'd like to post an event to our calendar, you can create a free account by clicking here. Note that free accounts do not have access to our subscriber-only content. |

Day pass subscribers

Are you a day pass subscriber who needs to log in? Click here to continue.

Roger Williams opens innovative state-of-the-art engineering building

Engineering, computer science and construction management hub already buzzing with activity

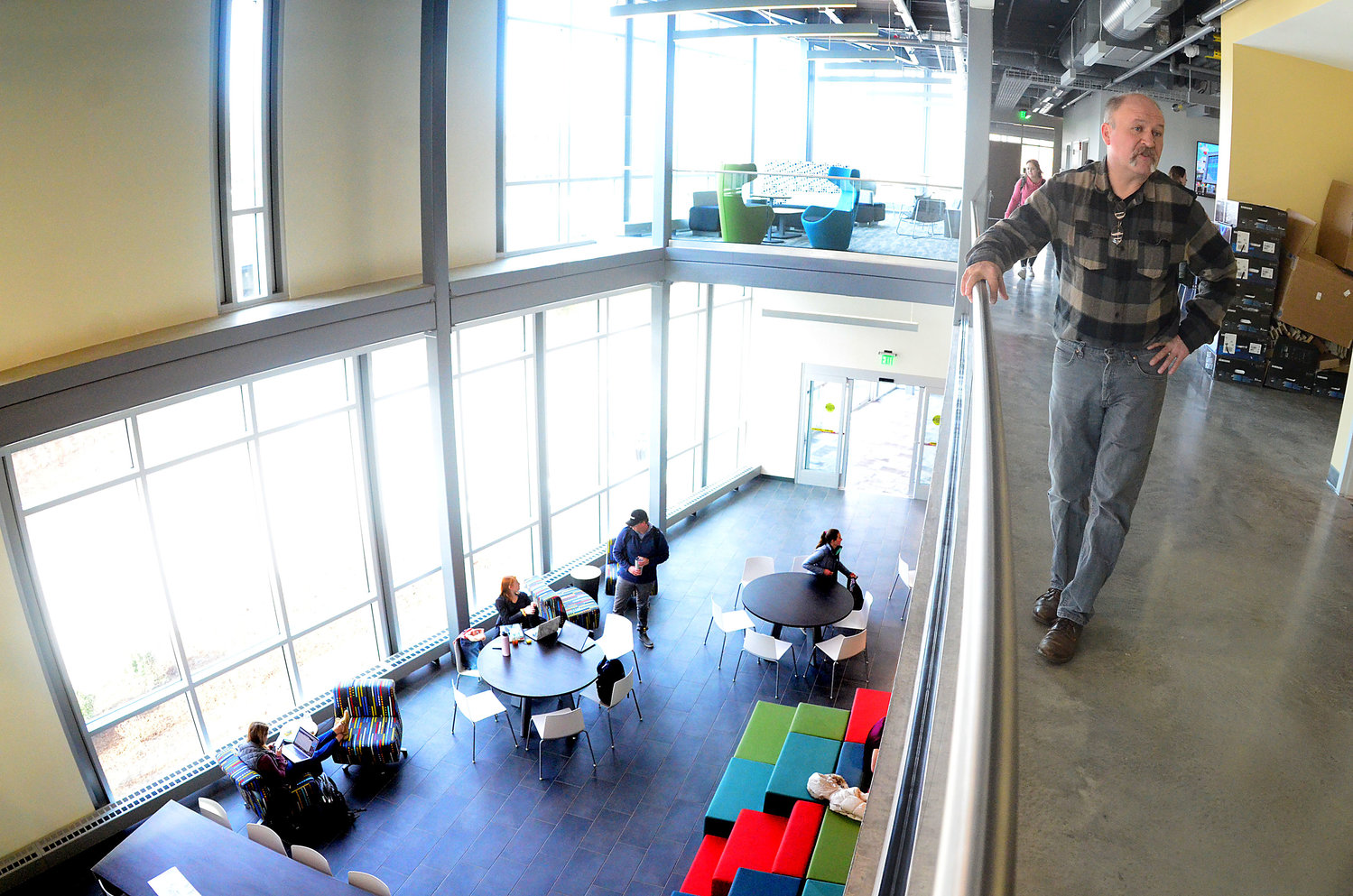

It’s been a busy year for Jim Dorothy, Roger Williams University professor and director of operations for their School of Engineering. The university’s latest addition, the SECCM Labs (SECCM stands for School of Engineering, Computing and Construction Management) has been taking shape at the center of campus, visible from Ferry Road for the better part of the past year.

Though not officially being dedicated until April 24, the building welcomed students on their first day back from break, last week.

For Mr. Dorothy and his colleagues, it’s a triumphant conclusion of a collaboration between Brewster Thornton Group architects, Shawmut design and construction, RWU facilities, faculty, and students, to bring it all together.

“For the past 10 years we’ve had an industrial space off Franklin Street called Hawkworks, where we did a lot of fabrication and construction work and instruction; now we’re bringing it all to campus,” Mr. Dorothy said. “We’re basically centralizing facilities.”

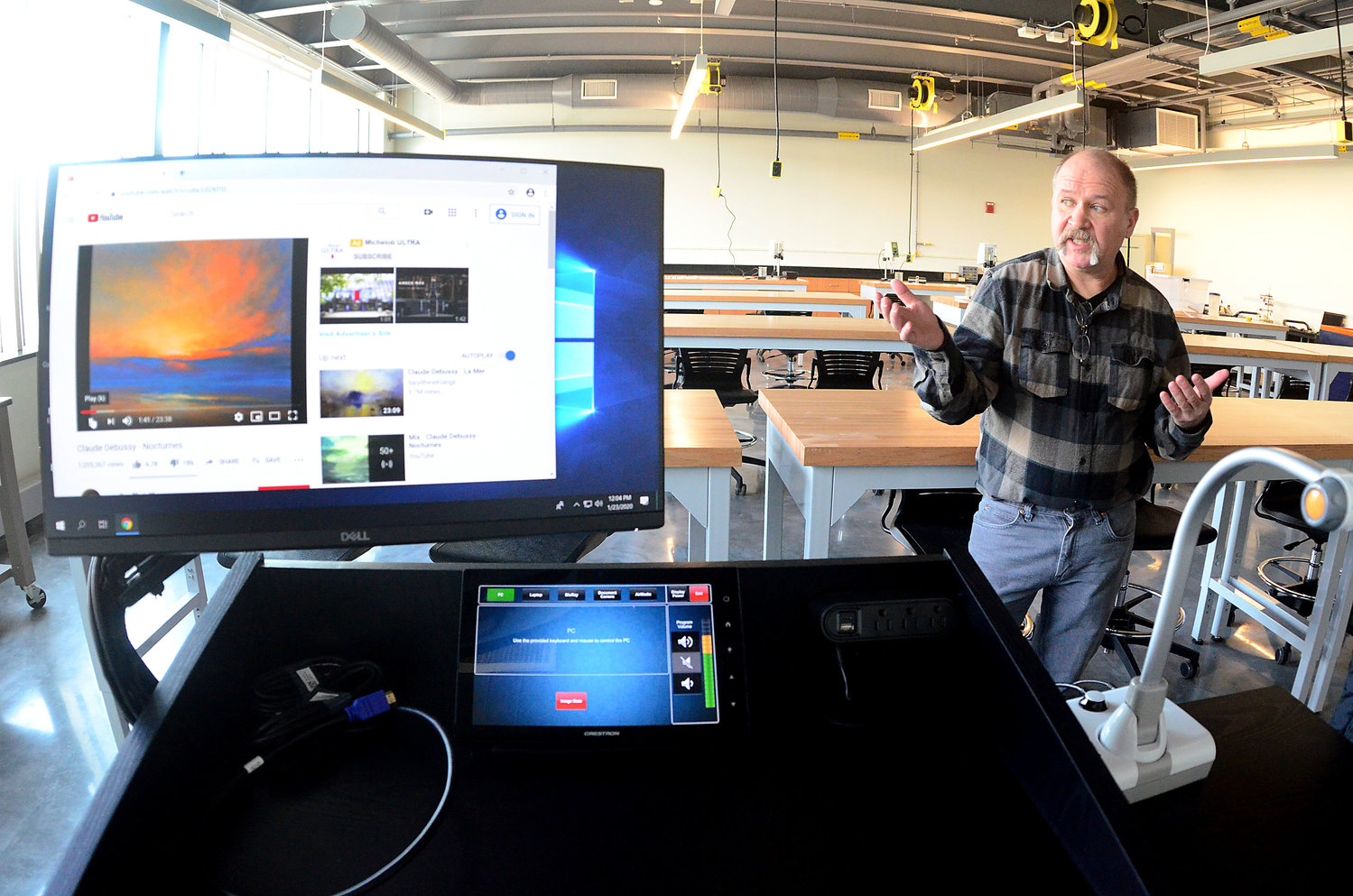

The result is a three-story, 27,000-foot building loaded with technology and teaching tools, like a massive overhead traveling crane students will use to erect steel structures and a lab that features a 28-foot-wide LED display for navigating through a 3D model of a building’s electrical and plumbing systems.

An addition to office, classroom, and independent and collaborative study areas, the building includes labs for Electrical Engineering, Mechanics of Materials, Engineering Fabrication, Construction Methods & Materials, Fluid Mechanics, Computer Science Software Experimentation, and Construction Management Emerging Technology. Each lab is equipped with technology that will allow for hands-on learning, from the crane in the high bay of the Construction Materials Lab — where students will build a small residential house — to a wind tunnel in the Fluid Mechanics Lab, to welding equipment in the Engineering Fabrication Lab, and a maker’s space with laser cutters and 3D printers.

Faculty will be teaching the theoretical elements behind these various engineering disciplines while at the same time offering opportunities for students to immerse themselves in real-world application of the concepts they’re learning in the classroom.

“We are trying to add a trade component to the program of study,” said Mr. Dorothy. “It’s part of their discipline to learn about the whole industry.”

One faculty member, for example, is collaborating with his students to fabricate a bicycle safety device that will allow parents riding with young children to control the braking system of the child’s bike.

The whole building is a classroom

The building itself is also a learning tool. The architects maintained exposed interior spaces and structured steel so faculty could instruct on acoustical decking, hot water piping, compressor units and more as real-world teaching moments.

“It’s engineering on display,” said Mr. Dorothy.

Throughout the project, Roger Williams faculty used SECCM Labs as an active learning project. Students got to go behind the scenes of construction, sit in on engineering and planning meetings, and intern with the management company that directed the entire project, from site planning to engineering, electrical and plumbing systems.

In the first days of its opening, students were settling into the new spaces, including an open group work space on the second floor and the sun-filled glass-fronted atrium on the first floor.

Lauren Donovan, a senior from Quincy Mass., is one of the students who is appreciating the new space, if only for one final semester. “It’s gorgeous. I’m very glad to get to see it and have classes in here before I graduate.”

Ms. Donovan, who has already signed an offer for a post-graduation position in Washington, DC, is typical of RWU’s Construction Management program — with both undergrad and graduate offerings, it’s considered one of the best in the country, and it boasts 100 percent job placement. With RWU’s investment in this new facility, they are hoping to grow enrollment in the school.

The project’s total cost was $13.8 million, with one third funded through philanthropy. And the SECCM Labs came in both on time and under budget — so if the students have learned their lessons from the example set by the team behind this project, they will leave their future clients well satisfied, indeed.

Other items that may interest you